Laser engraving is the method of leaving deep, indestructible traces on a steel floor. By focusing a laser beam in a predetermined sample on the steel floor, the incision is made, vaporizing some supplies to do away with them. Due to its sturdiness, distinctive resistance to corrosion hantencnc, and light-weight weight, aluminum has emerged as a flexible materials that has come to be required within the majority of industries. As a consequence of its quite a few processing choices, it supplies infinite design potentialities. In consequence, quite a lot of industries, together with aerospace, automotive, electronics, constructing, and development, have utilized it. As a result of it embeds everlasting codes on elements for simple traceability, laser slicing and engraving machine engraving in aluminum is a vital course of for marking components.

Proceed studying to study in regards to the workings of laser engraving in aluminum, its benefits and drawbacks, and design pointers for laser slicing machine engraving hjaluminumwindow half marking. Take a look at our information on direct and different half markings if you wish to study more about other forms of marking.

How Aluminum Laser Engraving ?

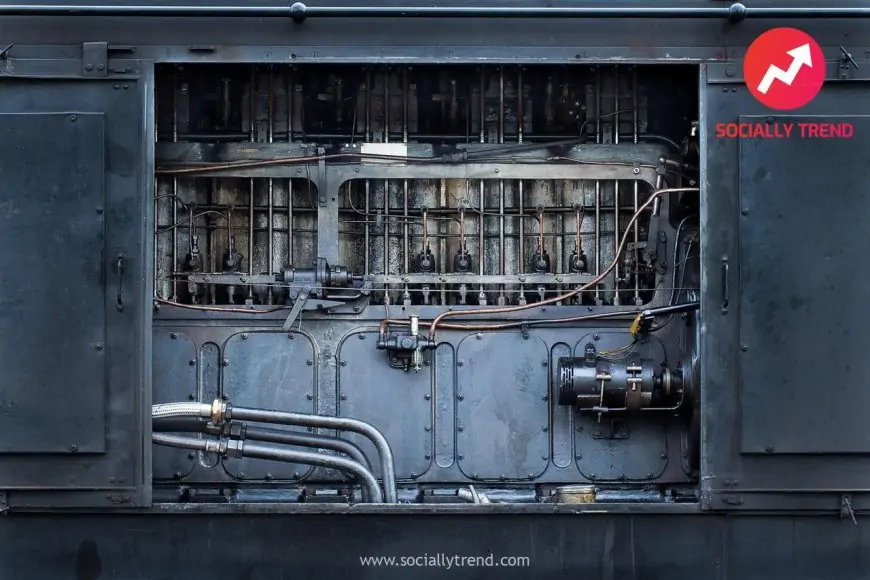

Works In aluminum laser engraving, a robust beam acts as a chisel, vaporizing particles from the steel floor to make deep marks. With the intention to keep away from abandoning a liquid residue, the laser engraver ought to emit sufficient power in order that the floor materials is worked up to its vaporization temperature, which for aluminum is 2,327 levels Celsius or 4,221 levels Fahrenheit. An air knife and a mechanism for eradicating fumes are two options of recent laser marking methods. The air knife protects the lens of the laser, and fume extraction retains dangerous fumes from getting into the office.

When engraving aluminum, two varieties of lasers are utilized: CO2 lasers and fiber laser methods. Fiber lasers function at a wavelength that interacts more successfully with metals. They're efficient at producing a sturdy, high-contrast mark with out compromising the components’ integrity. Moreover, they last more and are cheaper. Due to this, they're steadily used for marking industrial components. Aluminum could be engraved utilizing a CO2 laser engraving slicing machine as effectively; As a result of these lasers will also be used on components fabricated from wooden, pure stone, acrylic, and different non-metallic supplies, producers who work with a greater variety of supplies have a tendency to make use of them more steadily. Software program on a pc controls laser marking methods.

Laser marks fabricated from aluminum stay completely on the floor. As a result of aluminum workpieces are subjected to quite a lot of put on and floor remedies, that is significantly essential. Regardless of how lengthy a part lasts or what processes it goes via, engravings by no means break, tear, degrade, or are thrown away. In consequence, it's an acceptable marking methodology for elements that could be subjected to further rigorous remedies through the manufacturing course of, resembling shot blasting and sandblasting. If the appropriate machine is used, laser etching aluminum will also be higher for the atmosphere than different strategies of marking view more.

Why marking aluminum components is essential

Why mark aluminum components? Half marking, as beforehand acknowledged, makes it doable to exactly observe a part’s serial quantity by marking a QR code, information matrix code, or serial quantity. It additionally helps determine components and maintain observe of statistics within the manufacturing and utility of elements. In consequence, half marking is crucial for provide chain and high quality management features.

Extra causes for marking components embrace:

to differentiate components that look alike, to make it simpler to place components collectively, to link the half or product to the corporate and machine that made it, and for simple labeling.

Laser Engraving Naked vs. Anodized Aluminum

Each naked and anodized aluminum could be engraved with a fiber laser; nonetheless, engraving naked aluminum with a CO2 laser could be tougher than engraving anodized aluminum.

A fiber laser is the perfect system for engraving naked aluminum sheet steel. As a pretreatment for the steel, the operator of CO2 lasers is required to spray a particular paste. The chiseling agent is then adhered to the naked aluminum by the CO2 laser’s warmth. The process requires excessive energy configuration and takes time. The marks can simply wipe off if the work isn't achieved at a low velocity and with excessive energy settings, necessitating a second try. A CO2 laser could price more to hold out the identical activity due to these components. A CO2 laser marking, alternatively, doesn't take away any materials, so it doesn't compromise the integrity of the fabric.

However, engraving anodized aluminum is so simple as utilizing both form of laser. Aluminum coated with an oxide layer is known as anodized aluminum. The fabric is more immune to UV and corrosion because of this coating, which additionally supplies higher lubrication and low-cost upkeep. Whether or not fiber or CO2 laser engraving is used, engraving this type of aluminum is easy. In consequence, making a everlasting mark with low energy and price is less complicated. However, the convenience with which it's engraved could also be affected by the grade of anodized aluminum; Whereas Kind III sheets require the next energy output to chop via the anodized coating, Kind I and II anodized aluminum have thinner layers which can be simpler to engrave on.