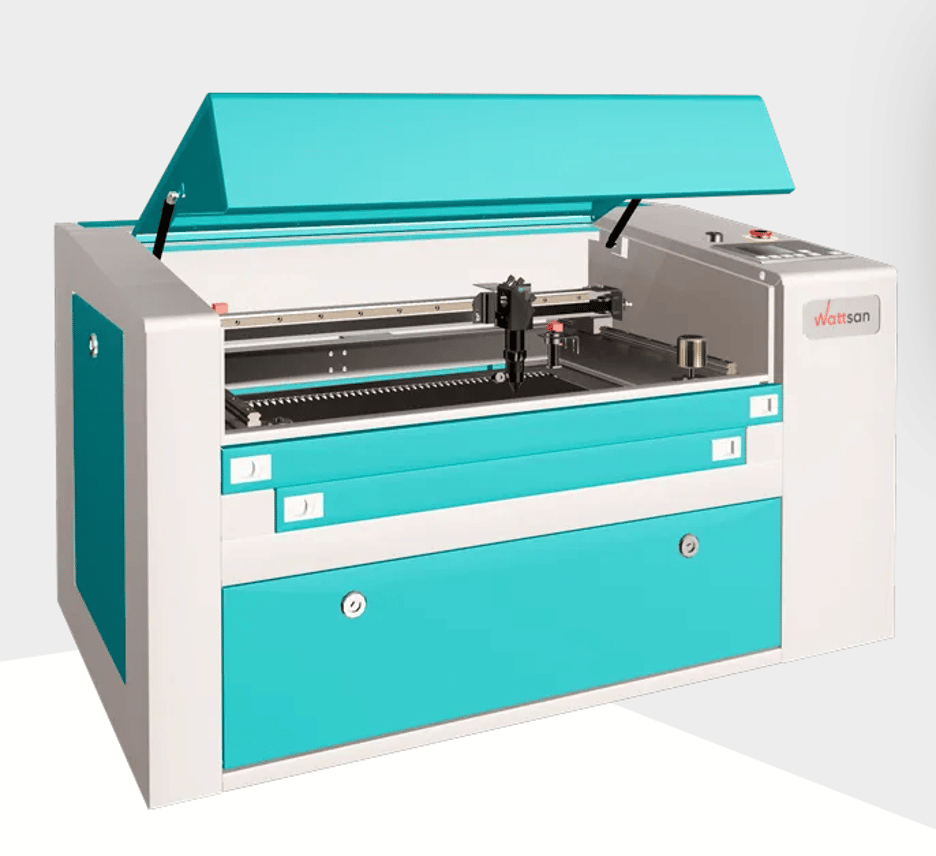

Virmer has launched Virmer fiber and Virmer co2 laser machines for the final 15 years. The robust demand for our merchandise in Europe outcomes from the truth that we don't compromise on high quality.

If you wish to mark steel, it's good to purchase a fiber laser. A CO2 laser is a wonderful possibility for preserving natural supplies comparable to material, wooden, or cardboard. A high-power CW (steady wave) fiber laser is more than likely wanted in case your software entails laser reducing metals. Different supplies, comparable to rubber and plastic, may be both one or the opposite. The principle distinction within the processing capabilities of every laser is its wavelength. A typical wavelength of a fiber laser is 1,060 nm. Laser beams are extremely concentrated, high-frequency gentle beams (amplifying gentle by stimulated emission of radiation). A robust beam can give attention to a small space. Each time a laser beam focuses on a cloth, the targeted space quickly heats up and converts the sunshine into warmth vitality.

When the recent materials melts and blows away, a gap creates in it. You need to use a laser reducing beam to chop varied supplies, from a small sheet of paper to a heavy steel plate. On different supplies, although, completely different laser varieties can produce blended outcomes.

A CO2 laser machine has a greater effectivity ranking than different gasoline lasers as a result of it could actually convert about 10-20% of {the electrical} enter energy into precious optical vitality. Most commercially out there machines use a CO2 laser with a wavelength of 10.6 m and a wavelength of 9 to 11 m. This makes it potential for the CO2 laser beam to cross by way of most supplies, together with wooden, plastic, and a few metals.

The 2 mostly used lead lasers for laser reducing are fiber and CO2 lasers. Their purposeful benefit distinguishes them from each other. A CO2 laser makes use of CO2 gasoline, however a fiber laser makes use of a solid-state medium, optical fiber.

Laser fiber

For prime-contrast markings comparable to steel annealing, etching, and engraving, fiber lasers work properly. They're a superb possibility for completely marking serial numbers, barcodes, and information matrices on metals as they produce a smaller focal diameter and are 100 instances more intense than CO2 methods. For functions comparable to direct element marking and product identification, fiber lasers are ubiquitous.

The truth that fiber lasers require no upkeep and have a protracted life is a major benefit (our lasers have a working lifetime of a minimum of 100,000). In comparison with CO2 lasers, they're additionally smaller. Fiber lasers eat a lot much less energy than CO2 lasers attributable to their excessive electrical effectivity, leading to a considerably decrease price of reducing functions.

Industrial cleansing functions, which embrace the removing of rust, paint, oxides, and different contaminants, are additionally seeing elevated demand for fiber lasers.

Relying on the makes use of you intend to place the fiber laser system to, the price will change dramatically. In demanding environments like ours, industrial fiber laser methods usually price between $40,000 and $1,000,000 for high-power laser reducing tools.

A fiber laser makes use of a strong optical fiber (fiber optic) cable as its receiving medium, in contrast to gas-based CO2 lasers.

Uncommon earth parts comparable to ytterbium, erbium, neodymium, dysprosium, praseodymium, thulium, and holmium are added to the fiber optic cable. The 4 energy sources are lasers, which connect with optical cables, laser diodes, and fiber optic cables.

The CO2 laser

Numerous non-metallic supplies, comparable to plastic, material, glass, acrylic, wooden, and even stone, may be marked with CO2 lasers. They're used to designate PVC pipes, development supplies, cell communication gadgets, electrical home equipment, prescribed drugs, meals packaging, built-in circuits, and digital elements.

A CO2 laser is genuine for reducing thicker supplies. When reducing materials wider than 5 mm, CO2 lasers present sooner preliminary penetration instances, straight line cuts, and smoother surfaces.

Sadly, CO2 lasers require far more energy than fiber lasers, which will increase their working prices. For instance, driving at most capability, a high-power CO2 laser and chiller will eat about 70 kW. Fiber lasers of comparable energy use nearly 18 kW.

Opposite to fashionable perception, CO2 lasers are more widespread. A hobbyist-grade K40 laser cutter can produce a 40-W CO2 laser beam that may reduce designs in paper, wooden engraving, ornamental laminates, acrylics, and even neon lighting. Due to their near-invisibility, CO2 laser beams additionally work in laser expertise for driverless automobiles.

Conclusion:

Whereas every laser has its benefits and particular functions, CO2 is the more established expertise, and fiber lasers are quickly outpacing it as the sphere evolves. The monetary advantages of using fiber lasers may be game-changing attributable to their velocity benefits, roughly half the working prices, and three- to 4 instances higher throughput than CO2 lasers. If you wish to begin an trade and you're discovering machines and tools to your manufacturing facility. Attempt to choose essentially the most appropriate Virmer machines that go well with you.